- Joined

- Dec 3, 2009

- Messages

- 22,403

- Reaction score

- 238

- Location

- Van Nuys Ca.

- My Bike Models

- 1983 Interstate

2018 KLR 650

2018 BMW S1000 RR

- My Bike Logs forum link

- https://classicgoldwings.com/forums/dan-filipi.122/

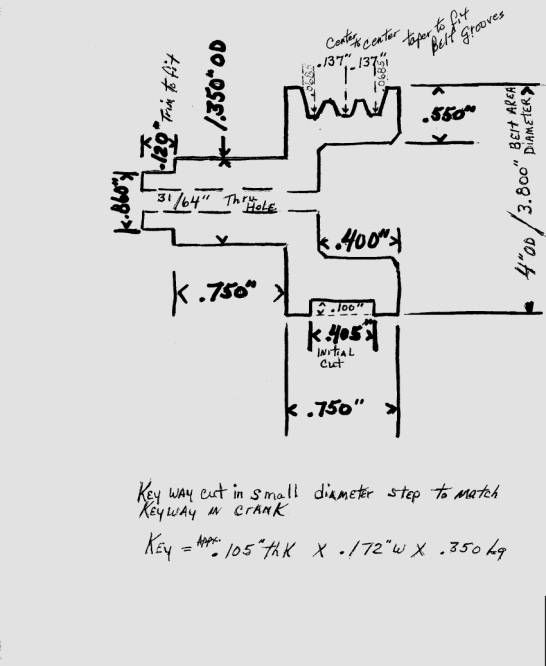

My pulley sit's flat against the end of the crankshaft as I can only imagine the others do also.

There is one important difference in mine, this is where the keyway comes in.

My pulley has a smaller center diameter which sits into the extension of the front timing belt pulley.

The key the pulley is taking advantage of is the one for the timing belt pulleys already there which sticks out just a tad further than the belt pulleys.

Where it says "Trim to fit" That is the extension that sits in the belt pulley.

The keyway dimensions are there just not on the drawing.

P.S. No need to trim anything to fit.

This pulley fits perfectly into the belt pulley when machined as drawn.

I would suggest though the pulley extension should be another 1/8" to aid in bolt and cover clearance.

This could be different on a 1200 but the drawing was made using a 1200 as a template.

There is one important difference in mine, this is where the keyway comes in.

My pulley has a smaller center diameter which sits into the extension of the front timing belt pulley.

The key the pulley is taking advantage of is the one for the timing belt pulleys already there which sticks out just a tad further than the belt pulleys.

Where it says "Trim to fit" That is the extension that sits in the belt pulley.

The keyway dimensions are there just not on the drawing.

P.S. No need to trim anything to fit.

This pulley fits perfectly into the belt pulley when machined as drawn.

I would suggest though the pulley extension should be another 1/8" to aid in bolt and cover clearance.

This could be different on a 1200 but the drawing was made using a 1200 as a template.