- Joined

- Dec 3, 2009

- Messages

- 10,979

- Reaction score

- 237

- Location

- Kingsport, Tennessee

- My Bike Models

- Former '82 GL1100 "The Slug"

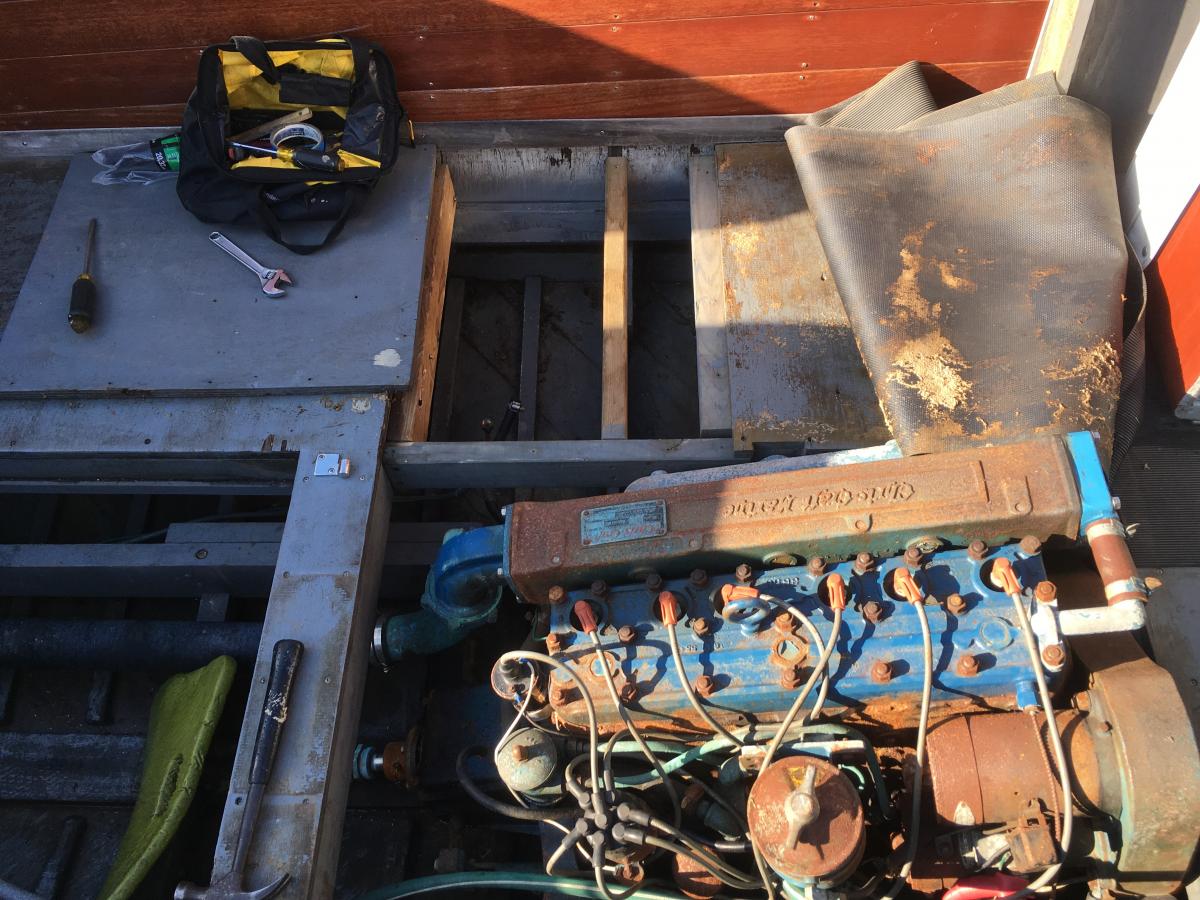

Some of you engine guys might appreciate this work. I have been slowly taking my 1956 KL engine apart for restoration and rebuilding work as needed. It is an original inline 6 cylinder, flathead Chris Craft KL engine. (Manufactured by Hercules Industrial Engines). I had an issue with water leaking from the head gasket on the right side of the engine. :shock:

Of course, my first instinct based on my Goldwing experience is "blown head gasket"! However, it turns out that the flathead engines have to be checked and re-torqued each season (who knew?). I got almost a full turn out of each of the 24 head bolts/nuts.

To be on the safe side, I decided to pull the head and determine for sure the gasket is not blown or that I have a crack anywhere. In the process, I have also been cleaning all of the parts as well as the block for painting.

Of course, my first instinct based on my Goldwing experience is "blown head gasket"! However, it turns out that the flathead engines have to be checked and re-torqued each season (who knew?). I got almost a full turn out of each of the 24 head bolts/nuts.

To be on the safe side, I decided to pull the head and determine for sure the gasket is not blown or that I have a crack anywhere. In the process, I have also been cleaning all of the parts as well as the block for painting.