i'm interested in the 4" pulley angela, i still have and ride my 1200 wing

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

4 inch pulley anyone?

- Thread starter dan filipi

- Start date

Help Support Classic Goldwings:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Dec 3, 2009

- Messages

- 22,463

- Reaction score

- 275

- Location

- Van Nuys Ca.

- My Bike Models

- 1983 Interstate

2018 KLR 650

2018 BMW S1000 RR

- My Bike Logs forum link

- https://classicgoldwings.com/forums/dan-filipi.122/

Some folks are saying a V belt pulley wouldn't be as thick as my 3 groove flat pulley.

Can someone measure the width of a V belt for me? I don't have one.

Can someone measure the width of a V belt for me? I don't have one.

Dan,dan filipi":iwchnv5x said:Some folks are saying a V belt pulley wouldn't be as thick as my 3 groove flat pulley.

Can someone measure the width of a V belt for me? I don't have one.

Vee belts are offered in a lot of different sizes.

https://www.gates.com/catalogs/file_disp ... 5Ccatalogs

- Joined

- Dec 3, 2009

- Messages

- 22,463

- Reaction score

- 275

- Location

- Van Nuys Ca.

- My Bike Models

- 1983 Interstate

2018 KLR 650

2018 BMW S1000 RR

- My Bike Logs forum link

- https://classicgoldwings.com/forums/dan-filipi.122/

WindNWing":2gtudy6s said:Dan,dan filipi":2gtudy6s said:Some folks are saying a V belt pulley wouldn't be as thick as my 3 groove flat pulley.

Can someone measure the width of a V belt for me? I don't have one.

Vee belts are offered in a lot of different sizes.

https://www.gates.com/catalogs/file_disp ... 5Ccatalogs

Forgot about that.

Whats a common car V belt width?

fysty-1

Well-known member

- Joined

- Jan 8, 2011

- Messages

- 244

- Reaction score

- 1

- Location

- Surrey, B.C. Canada.

- My Bike Models

- Baby Blue sold due to health issues.

If there is no answer befor I get back, I'll find out.dan filipi":pewnvu2h said:WindNWing":pewnvu2h said:Dan,dan filipi":pewnvu2h said:Some folks are saying a V belt pulley wouldn't be as thick as my 3 groove flat pulley.

Can someone measure the width of a V belt for me? I don't have one.

Vee belts are offered in a lot of different sizes.

https://www.gates.com/catalogs/file_disp ... 5Ccatalogs

Forgot about that.

Whats a common car V belt width?

$55.09

$58.00

WILD HEART Waterproof Motorcycle Duffel Bag PVC500D Double-bottom With Rope Straps and Inner Pocket 40L 66L 100L for Kayaking, Camping, Boating,Motorcycle

ZHONGSHAN WILD FRUIT OUTDOOR

$48.99

$55.00

HONDA GL1000 & GL1100 GOLDWING MOTORCYCLE REPAIR SHOP & SERVICE MANUAL For 1975, 1976, 1977, 1978, 1979, 1980, 1981, 1982, 1983, 1984 & 1985 - NEW, 304 Pages

Classic Automotive Repair Shop & Restoration Manuals

$76.00

Honda GL 1800 Gold Wing 2001-2010 Repair Manual (Haynes Service & Repair Manual)

Clickgoodwill

$14.99

$17.99

MELASA Fleece Lined Winter Cycling Beanie with Holes for Glasses - For Men, Women

HNXCHUANG

$150.00

1984 Honda Gold Wing GL1200 Factory Service Manual Dealer GoldWing Shop Repair Workshop

GLAVIS ENTERPRISES

$41.81

$54.95

Clymer Honda GL1200, 1984-1987: Maintenance, Troubleshooting, Repair (Clymer Motorcycle)

Haynes Repair Manuals

$129.00

Sena 30K / 20S / EVO Helmet Clamp Kit for Honda Goldwing CB Helmet Accessories

ProRidersClub

$32.09

$59.95

Honda GL1800 Gold Wing 1800 (01-10) Haynes Repair Manual (Paperback)

Haynes Repair Manuals

$35.37

$45.95

Show Chrome Accessories 52-696 Honda Goldwing GL1800 01-10 Radio Panel

Amazon.com

$100.00

$169.99

1988 Honda Gold Wing GOLDWING GL1500 Service Shop Repair Manual OEM FACTORY 88

GLAVIS ENTERPRISES

$46.95

Harley-Davidson Trailblazer #1 Logo Duffel Bag w/Adjustable Strap - Rust Vintage Large

Wisconsin Harley-Davidson

$9.95

$14.95

BELL Vortex Hinge Plate Kit Street Motorcycle Helmet Accessories - Black/One Size

Movatik

$50.07

M506-2 1993-2000 Honda GL1500 Goldwing Clymer Motorcycle Repair Manual

Classic Automotive Repair Shop & Restoration Manuals

$79.95

Harley-Davidson Water-Resistant Travel Hybrid Duffel Bag/Backpack - Black

Wisconsin Harley-Davidson

for that small of a belt 1/2' is on the big side ...3/8" will probably get mor traction in v belts

- Joined

- Dec 3, 2009

- Messages

- 22,463

- Reaction score

- 275

- Location

- Van Nuys Ca.

- My Bike Models

- 1983 Interstate

2018 KLR 650

2018 BMW S1000 RR

- My Bike Logs forum link

- https://classicgoldwings.com/forums/dan-filipi.122/

The 3 groove flat is 3/8" wide so I think a flat and V pulley are close to the same

i would have to agree. i didn't realize the 4" pulley was a three groove. i was thinking 4 groove. don't know why.

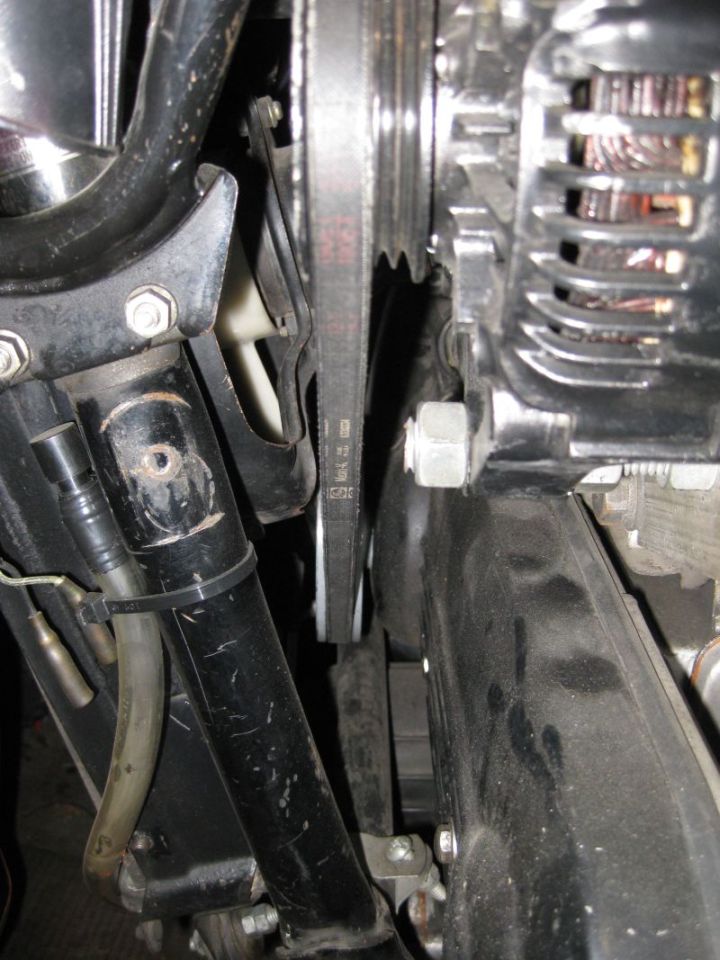

your picture shows a very similiar install to mine. different paths..same great outcome. looking forward to seeing it at the CG meet in august :music:

your picture shows a very similiar install to mine. different paths..same great outcome. looking forward to seeing it at the CG meet in august :music:

badorderbob

Well-known member

Hi, I've been following this thread with great interest and wouldn't mind using a V pulley just as stated because of room. Do you think one could use a Poly type pulley? And what might a price be for one made using the same format as the 4 inch pulley but one maybe made for a 3'' or 3 1/2" pulley in aluminum or poly??

i would think a poly would work. i went the REAL "poorboy" route. i used a lawnmower pulley i had laying around that had the correct size hole, and welded up the bearing to make it one piece, and manufactured a spacer out of an aluminum existing spacer with correct hole size. bought a longer bolt. pulley is about the same size as the alt. pulley. (can be bought new for less then $15 ) not high tech, but has worked very well for over 5 years. i just didn't see any reason to over think it. not saying its the only, or even the best way. just the way i did it

i would say and know that aluminum v pully tho everywhere are bad choice as they have stress spliting pressure put on them by the way v belts work ...id say poly would be the same ....they are better suited for flat pulley that could be machined reinforce better :smilie_happy: :smilie_happy: of corse i used electric motors and stuff that are so much more demanding than altinator ...as cyborb says i would have done something simular to what he did and obviously its worked fine ....over thinking can be a huge problem in getting something done

my pulley is steel, and machined. not the two piece welded together. i agree on the aluminum. the only aluminum i used was for the spacer. also for the tensioner i used a chevy alt adjuster. the curved metal with a long slot in one end and a hole in the other. mounting the alt. pivoit point on the top fron motor mount, and the adjuster on the opposite top front motor mount. i used a chrome one from the auto parts store. looks pretty, and does not have to be modified

badorderbob

Well-known member

cyborg":3d0x5sva said:i would think a poly would work. i went the REAL "poorboy" route. i used a lawnmower pulley i had laying around that had the correct size hole, and welded up the bearing to make it one piece, and manufactured a spacer out of an aluminum existing spacer with correct hole size. bought a longer bolt. pulley is about the same size as the alt. pulley. (can be bought new for less then $15 ) not high tech, but has worked very well for over 5 years. i just didn't see any reason to over think it. not saying its the only, or even the best way. just the way i did it I like the way you think Cyborg,......REAL "poorboy" :smilie_happy: :smilie_happy:........LOL :salute: !! I'm like you, trying to keep it simple and with in due bounds of my wallet,...... CHEAP :hihihi: !!!! Thanks :hi: Bob

don't know where you are in indiana, but when you get it done i would lke to see it.. you know, "show me yours,....i'll show you mine". a bunch of guys are getting together the first weekend in may in aroura, (spelled wrong) in. real near cincinati. come on over snd we can compare notes

badorderbob

Well-known member

Thanks for the Invite,..... I'm in Ft. Wayne N.E. corner!! :thanks: :hi: Bob

- Joined

- Dec 3, 2009

- Messages

- 22,463

- Reaction score

- 275

- Location

- Van Nuys Ca.

- My Bike Models

- 1983 Interstate

2018 KLR 650

2018 BMW S1000 RR

- My Bike Logs forum link

- https://classicgoldwings.com/forums/dan-filipi.122/

cyborg":3m7shwqk said:my pulley is steel, and machined. not the two piece welded together. i agree on the aluminum. the only aluminum i used was for the spacer. also for the tensioner i used a chevy alt adjuster. the curved metal with a long slot in one end and a hole in the other. mounting the alt. pivoit point on the top fron motor mount, and the adjuster on the opposite top front motor mount. i used a chrome one from the auto parts store. looks pretty, and does not have to be modified

It didn't happen if there aint no pics :mrgreen:

i guess it didn't happen then :yes: i can't really do pics. but we will meet up someplace, some time, and you can check it out.

actually dan, i will try and get some sorts pictures to you on your email. if you want to post them, its o.k. by me

actually dan, i will try and get some sorts pictures to you on your email. if you want to post them, its o.k. by me

fysty-1

Well-known member

- Joined

- Jan 8, 2011

- Messages

- 244

- Reaction score

- 1

- Location

- Surrey, B.C. Canada.

- My Bike Models

- Baby Blue sold due to health issues.

Gentlemen, I have just heard from a friend who is a machinist with a big firm near Toronto Ont & say with an intial order of 60 we should get them @ about $35.00 each Cnd. I figure if Dan handles this then there shoul be about 15-20 buck for shipping( still super cheap). I don't know how it would work but I guess the best way would be to send Dan the $$$'s and He could ship them out. So far I have Tomahawk, tumunga, detdrbuzzard, littlebeaver, mcgovern61 <>, & myself from this forum and after posting this I am going over to my other wing forums to compile a list there. I mention to Dan that I thought these should be done in Aluminum to cut down on rolling mass. If there are any others please chime in & I will add you to the list. Thanks Angela aka fysty-1 :clapping: :clapping: :clapping: :Egyptian: :Egyptian: :Egyptian: