I think just read it.?? Dan will tell us. It would be nice to have them all Adobe off on our phones. No wifi or data needed then. I have a75-79 on my old phone that way. Pretty handy if you break down.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

'84 1200 engine for a '82 GW

- Thread starter canuckxxxx

- Start date

Help Support Classic Goldwings:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Dec 3, 2009

- Messages

- 9,291

- Reaction score

- 337

- Location

- Duncanville, Texas

- My Bike Models

- 1981 GL1100 Innerstate("The Turd")SOLD!!, 1996 GL1500 Innerstate

I don't think you can d-load the whole manual from the Gallery, but you can d-load individual pages. I think Dan has the original files for the manuals that he may be able to send via email, but I think the file size would be enormous....most email services would not allow it...

I have always just printed out the page(s) that I need for a specific job, and went from there. :laptop:

I have always just printed out the page(s) that I need for a specific job, and went from there. :laptop:

I just figured out another way that you can save information without having Wi-Fi. You can only do one page at a time, but open the page that you need then save it to your reading list. This will let you view them in your reading list without wifi or cellular data. I just saved the entire chapter on the stator. It would be nice to then be able to condense it to a folder, but that's still above my skill set.

I have an iPhone 6+

I have an iPhone 6+

[url=https://www.classicgoldwings.com/forum/viewtopic.php?p=151654#p151654:247djvia said:ekvh » Wed Jun 24, 2015 2:58 pm[/url]":247djvia]

You could get a look at the cams for anything obvious there, but the 1200 valve train hides a lot compared to early models. A total long shot of good luck might be a valve stuck open with the lifter not bled yet. Likely worse, ---- or better in my opinion. Now you have an excuse to put early heads on with more radical cams. Do it. Do it.Do it.Do it.

Eric, when I look at the specs for a GL1100; 1080cc, 65lb-ft, 81hp and compare with a GL1200; 1180cc, 77lb-ft, 94hp. That is a 9% increase in displacement but a 18% increase in torque, 16% increase in HP. I figure Honda must have come up with something that works really well with the 1200s. Smaller valves/ports, and cam profiles to match. I think I read somewhere where they went for increase in charge velocity, rather than flow, in order to maximize performance.

With my riding style, I value low end torque and I figure the stock 1200 should do it. Also the stock setup will be simpler and less expensive to put together.

But this is early and who knows where it will end up.

Brian

well i went to the simplisity route ...when doing hooch ...to me 1200 heads are jusr user unfriendly ...and seem to have all the low end torque one could want with earlier heads and bigger valves ....i really just dont like the 1200 heads ...

I'm already starting to not like the auto valve adjust.

$100.00

$169.99

1988 Honda Gold Wing GOLDWING GL1500 Service Shop Repair Manual OEM FACTORY 88

GLAVIS ENTERPRISES

$76.00

Honda GL 1800 Gold Wing 2001-2010 Repair Manual (Haynes Service & Repair Manual)

Clickgoodwill

$50.07

M506-2 1993-2000 Honda GL1500 Goldwing Clymer Motorcycle Repair Manual

Classic Automotive Repair Shop & Restoration Manuals

$55.09

$58.00

WILD HEART Waterproof Motorcycle Duffel Bag PVC500D Double-bottom With Rope Straps and Inner Pocket 40L 66L 100L for Kayaking, Camping, Boating,Motorcycle

ZHONGSHAN WILD FRUIT OUTDOOR

$150.00

1984 Honda Gold Wing GL1200 Factory Service Manual Dealer GoldWing Shop Repair Workshop

GLAVIS ENTERPRISES

$33.40

$45.95

Show Chrome Accessories 52-696 Honda Goldwing GL1800 01-10 Radio Panel

Amazon.com

$33.34

$59.95

Honda GL1800 Gold Wing 1800 (01-10) Haynes Repair Manual (Paperback)

Haynes Repair Manuals

$41.76

$54.95

Clymer Honda GL1200, 1984-1987: Maintenance, Troubleshooting, Repair (Clymer Motorcycle)

Haynes Repair Manuals

$48.99

$55.00

HONDA GL1000 & GL1100 GOLDWING MOTORCYCLE REPAIR SHOP & SERVICE MANUAL For 1975, 1976, 1977, 1978, 1979, 1980, 1981, 1982, 1983, 1984 & 1985 - NEW, 304 Pages

Classic Automotive Repair Shop & Restoration Manuals

$129.00

Sena 30K / 20S / EVO Helmet Clamp Kit for Honda Goldwing CB Helmet Accessories

ProRidersClub

$42.99

$45.25

BELL Star Series 2016 Hinge Plate Kit Street Motorcycle Helmet Accessories - Black/One Size

PERF-MOTO

I wish I could afford a dyno run as that would tell a lot. I realize a lot of the first mods to these also had much lower gearing too, and perceived performance could be due to that. Joe now has a 1200 rear end on his and likes it. No real way to know for sure about the numbers, but compared to my stock 77, the torque difference is pretty big, but 18% bigger displacement, with slightly longer stroke. It may just be from that. I wish I had a stock 1200 to drive to compare.

well i did and it was va standard ...there was no comparison at all ..the 1200 standard stuggle some like 1100s do around my place with the grade...hooch never has labor around here even with 1200 rear end .....so i am convinced through my own experiences that the hooch modified is way better than stock honda

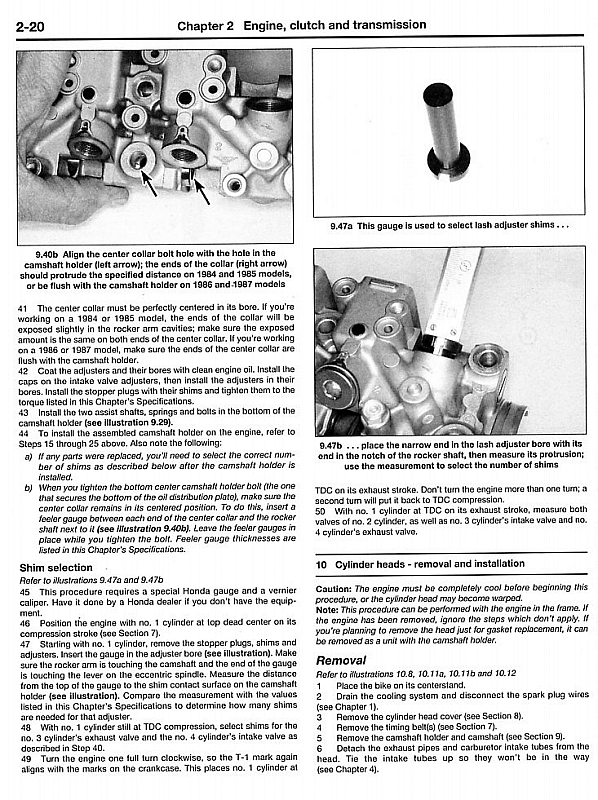

Just reading the Haynes manual about the auto valve adjusters on the 1200 engine. The hydraulic adjusters are in bores in the cam holders. The ends of these bores have an end caps. There are shims that are supposed to go under the end caps to give the correct length fit of the adjuster in the bores.

When I look at my heads I can see that all the end caps on both heads have shims except the end caps for #2 intake and exhaust. Without shims the end cap will push the adjuster further down against the rocker shaft, maybe causing it to stay open. Just a theory at this point. BTW these shims are look to be fairly thick...1/16" or so.

Apparently there is a tool to determine the shims thickness to use. Will have to try and figure out how to get or make this tool.

Anyone else play with this stuff on a 1200 head? Experiences?

Thanks

Brian

When I look at my heads I can see that all the end caps on both heads have shims except the end caps for #2 intake and exhaust. Without shims the end cap will push the adjuster further down against the rocker shaft, maybe causing it to stay open. Just a theory at this point. BTW these shims are look to be fairly thick...1/16" or so.

Apparently there is a tool to determine the shims thickness to use. Will have to try and figure out how to get or make this tool.

Anyone else play with this stuff on a 1200 head? Experiences?

Thanks

Brian

- Joined

- Dec 3, 2009

- Messages

- 22,460

- Reaction score

- 275

- Location

- Van Nuys Ca.

- My Bike Models

- 1983 Interstate

2018 KLR 650

2018 BMW S1000 RR

- My Bike Logs forum link

- https://classicgoldwings.com/forums/dan-filipi.122/

Susie's 1200 I worked had at least one valve with no shims that measured out correct.

I thought I sent you a pm already but I had a tool made to measure and one of the members here drew up matchining specs to make it, it's in the gallery.

I thought I sent you a pm already but I had a tool made to measure and one of the members here drew up matchining specs to make it, it's in the gallery.

- Joined

- Dec 3, 2009

- Messages

- 22,460

- Reaction score

- 275

- Location

- Van Nuys Ca.

- My Bike Models

- 1983 Interstate

2018 KLR 650

2018 BMW S1000 RR

- My Bike Logs forum link

- https://classicgoldwings.com/forums/dan-filipi.122/

That's the tool and specs drawn by Ken Lind.

All you really need to measure for the shims is a stick of some kind like a straw with a mark on it the exact length of the tool from tip to top of that tool spec, 2.225 inches, and a mm ruler or caliper to find the shim thickness needed.

The manual has a range thickness they fall under according to the measurement you get.

Thanks Dan. I think I will ask my machinist friend to make a shim selector tool for me. I figure, as long as I have that engine in my bike (and I hope it is for a long time) I will need to check the shims from time to time so may as well have the right tool.

Here is something I discovered: I figured that once I backed off the valve adjuster end caps (where the shims go) and bolted the rocker holder down onto the cam, the rocker shafts would rotate to a slack position...but they don't. The valves were still held open. I had to take the rocker shaft end caps out, put a screw driver in the slot of the rocker shaft and rotate the shaft to the upper most position and then tighten the rocker holder bolts (but not having the bolts in the end holes). Then I had the rocker holder bolted down and the rockers loose.

At that point I could screw the adjuster end caps down until there was no clearance or whatever clearance I wanted. This gives me an idea: If I wanted to dispense with the hydraulic auto adjusters, I could have metal slugs made up, similar to the shim tool but shorter and put those in place of the auto-adjusters. Then you could adjust the valve clearance the old fashioned way, with a feeler gauge and maybe putting shims under the end caps. Just a thought. I will still try and get the auto adjust system to work because it should be quieter running and work better as long as it is working properly.

Brian

Here is something I discovered: I figured that once I backed off the valve adjuster end caps (where the shims go) and bolted the rocker holder down onto the cam, the rocker shafts would rotate to a slack position...but they don't. The valves were still held open. I had to take the rocker shaft end caps out, put a screw driver in the slot of the rocker shaft and rotate the shaft to the upper most position and then tighten the rocker holder bolts (but not having the bolts in the end holes). Then I had the rocker holder bolted down and the rockers loose.

At that point I could screw the adjuster end caps down until there was no clearance or whatever clearance I wanted. This gives me an idea: If I wanted to dispense with the hydraulic auto adjusters, I could have metal slugs made up, similar to the shim tool but shorter and put those in place of the auto-adjusters. Then you could adjust the valve clearance the old fashioned way, with a feeler gauge and maybe putting shims under the end caps. Just a thought. I will still try and get the auto adjust system to work because it should be quieter running and work better as long as it is working properly.

Brian

the 1200s have 11% more oil flow than 1000s or 1100s probably cause of the hydro heads ..hooch with 1100 heads is the quietest wing ive had ..so im not so sure the hydro head would be any quieter.....

- Joined

- Dec 3, 2009

- Messages

- 22,460

- Reaction score

- 275

- Location

- Van Nuys Ca.

- My Bike Models

- 1983 Interstate

2018 KLR 650

2018 BMW S1000 RR

- My Bike Logs forum link

- https://classicgoldwings.com/forums/dan-filipi.122/

The hydraulic adjusters are designed to eliminate the need for periodic adjustments and works very well. Can't even hear the valves on mine.

I think some would fault it because they don't understand how they work.

It really is a very ingenious design.

I think some would fault it because they don't understand how they work.

It really is a very ingenious design.

OK, I'm going to make it work. At least I know now that there is a position where the valves are no held open. I was thinking there was something majorly wrong (or it was posessed) when I had the end caps backed off to loose and the valves were still being held open.

Thanks guys

Brian

Thanks guys

Brian

- Joined

- Dec 3, 2009

- Messages

- 22,460

- Reaction score

- 275

- Location

- Van Nuys Ca.

- My Bike Models

- 1983 Interstate

2018 KLR 650

2018 BMW S1000 RR

- My Bike Logs forum link

- https://classicgoldwings.com/forums/dan-filipi.122/

Have to keep in mind that these hydraulic adjusters do not work like hydraulic lifters on a car engine.[url=https://www.classicgoldwings.com/forum/viewtopic.php?p=152001#p152001:2dn248sz said:canuckxxxx » 6 minutes ago[/url]":2dn248sz]

OK, I'm going to make it work. At least I know now that there is a position where the valves are no held open. I was thinking there was something majorly wrong (or it was posessed) when I had the end caps backed off to loose and the valves were still being held open.

Thanks guys

Brian

They turn a offset pin to get the correct tappet lash while running.

The only similarity to hydraulic lifters is that they do need to be pumped up with oil but that's where the similarity stops. These get pumped up when they get sufficient oil pressure then they can work their magic.

There is a good cutaway view of the system in one of the manuals.

Aside from the initial shim adjustment and making sure those offset pins rotate smooth, there really is nothing to "fix" on them.

I mean, what more does a valve tappet need than a perfect lash adjustment all the time.

So with the cam lobs for #2 pointed down and the rocker assembly bolted onto the head I made some shim measurements. I ground a 7/16" bolt down to exactly 2.225" total length. Put it into the lifter bore and measure the height above the shim surface with it pushed down enough to eliminate any rocker clearance.

For intake I measured .450"

for exhaust .485"

So according to the table in the Honda shop manual there should be 2 shims under each of the end caps. Mine had no shims! :shock: So to me that explains why the valves for #2 were being held open.

Brian

For intake I measured .450"

for exhaust .485"

So according to the table in the Honda shop manual there should be 2 shims under each of the end caps. Mine had no shims! :shock: So to me that explains why the valves for #2 were being held open.

Brian

slabghost

Well-known member

Nice quick way to make the tool! Be sure to mark it as a tool so you don't use it elsewhere.

- Joined

- Dec 3, 2009

- Messages

- 22,460

- Reaction score

- 275

- Location

- Van Nuys Ca.

- My Bike Models

- 1983 Interstate

2018 KLR 650

2018 BMW S1000 RR

- My Bike Logs forum link

- https://classicgoldwings.com/forums/dan-filipi.122/

I'm not sure what affect lapping valves has on that measurement, if it would require more shim or less but your measurement method seems to be accurate: