ok the battle of the leaves is getting handle on all fronts fronts ...sides ..back ...what a battle this yr ...anyway iwill celebrate the ending war of leaves with some work on the dragonwing its starting to look like i will use dyna S ignition and coils as i just cant get my head or all the parts i might need for the sticks to work but you never know what i might do during the project time...ill take some pics if i get very far and there something to see :mrgreen:

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

mongruel getting a 86 1200 engine added to the bloodline

- Thread starter joedrum

- Start date

Help Support Classic Goldwings:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

small update got the starter tested today and it it worked ...spun the motor just fine with the plugs anyway and no hitting to be heard .... :mrgreen: always nice when a ebay part works...been discussing things with slab and i think i have the ignition set up i want figured out the way i want it to test the motor soon ...its nice here weatherwise and i should be able to get quite a bit done to it ....getting close.... :builder:

been having computer problems ....need to stay away from it today ....every time i look at it something gose wrong ...so its a perfect day to work on bike ...

nice temps outside right now early this morning ...wet out from all the rain ...nice and dry inside the dog house where the dragonwing is at....ill keep the camera with me and hopefuly gets some good pics :builder: :mrgreen:

nice temps outside right now early this morning ...wet out from all the rain ...nice and dry inside the dog house where the dragonwing is at....ill keep the camera with me and hopefuly gets some good pics :builder: :mrgreen:

okay not much progress lately but some ,,,ive been in the back of bike by battery going through the wiring around the solenoid ...i have the battery ...rectifier...30amp fuse hot to key switch and the relay battery power all hooked up to battery side of solenoid...i cut off the plastic top of solenoid so i could get everything hooked up and you can see the condition of things and clean later....im going with the dyna coils i have and dyna ignition .....this will eliminate the ballist resistor....so on the wiring of the 77 from the keyswitch the power comes out of the black wire and gose down in the shelter ....from the kill switch a black and brown wire comes down to the shelter ...in the stock form this is where the ballist is installed...going in the ballist from keyswitch black wire and going out the ballist to the black and brown going to kill switch...on this bike the black and black and brown wire will be pluged together as ballist wont be use here ....now as things go here on early 1000s you have two power sorces going to right hand grip one from bown and black wire formaly from resitor to kill switch the other gose to the starter button and is black wire hot from keyswitch...black wire from keyswitch only comes in play button in on starter button to deliver full power to coils ballist bypassed then gose to killswitch and then to coils with button in .....button out power to run bike comes brown and black wire....be back later to finish rambling

.....button out power comes from the black and brown wire ...the out put power wire from the ballist in stock form.....

from there the power gose through kill switch and to the coils in the black and white wires that go to the coils ......so im figuring this is where the trigger wire must go to activate the relay when key is on and kill switch in run posistion ...if off on kill switch the relay would turn off too ....triggered anywhere before this point the kill switch wouldnt turn off ignition relay ?....thats my figuring....pass the kill switch the black and white wires go to the coils ....im thinking in my set up after attaching to relay trigger wire thats it on black and white wire now dont have to go to coils .....once the power is triggered in relay the output side of relay hooks to the dyna power wire for the slight power it needs and gose to coils also to deliver full battery power to coils to fire .... :heat: ...my fingers and brain peaking ....anyway if anyone can read this rambling and differ or agree please comment :mrgreen:

from there the power gose through kill switch and to the coils in the black and white wires that go to the coils ......so im figuring this is where the trigger wire must go to activate the relay when key is on and kill switch in run posistion ...if off on kill switch the relay would turn off too ....triggered anywhere before this point the kill switch wouldnt turn off ignition relay ?....thats my figuring....pass the kill switch the black and white wires go to the coils ....im thinking in my set up after attaching to relay trigger wire thats it on black and white wire now dont have to go to coils .....once the power is triggered in relay the output side of relay hooks to the dyna power wire for the slight power it needs and gose to coils also to deliver full battery power to coils to fire .... :heat: ...my fingers and brain peaking ....anyway if anyone can read this rambling and differ or agree please comment :mrgreen:

- Joined

- Dec 3, 2009

- Messages

- 22,443

- Reaction score

- 262

- Location

- Van Nuys Ca.

- My Bike Models

- 1983 Interstate

2018 KLR 650

2018 BMW S1000 RR

- My Bike Logs forum link

- https://classicgoldwings.com/forums/dan-filipi.122/

That sounds like the right trigger wire to me,

Course I can't be of much help because the manuals wiring diagrams are wrong

Course I can't be of much help because the manuals wiring diagrams are wrong

$39.95

$49.95

Honda GL1500 Gold Wing Motorcycle (1993-2000) Service Repair Manual

Haynes Repair Manuals

$39.95

$59.95

Honda GL1800 Gold Wing 1800 (01-10) Haynes Repair Manual (Paperback)

Haynes Repair Manuals

$44.95

Harley-Davidson Bar & Shield Logo Zipper Rugged Graphic Duffel Bag - Black

Wisconsin Harley-Davidson

$37.98

$54.95

Clymer Honda GL1200, 1984-1987: Maintenance, Troubleshooting, Repair (Clymer Motorcycle)

Empty Estates

$89.95

Harley-Davidson Trailblazer Hop Along Travel Duffel Bag - Black/Rust Vintage X-Large

Wisconsin Harley-Davidson

$40.06

$45.95

Show Chrome Accessories 52-696 Honda Goldwing GL1800 01-10 Radio Panel

Amazon.com

$36.92

$45.95

Triumph Bonneville T100, T120, Bobber, Thruxton, Street Twin, Cup & Scrambler (2016 - 2017) Haynes Repair Manual (Haynes Powersport)

Goodwill of Silicon Valley

$31.29

$33.45

Show Chrome Accessories 52-647 Chrome Instrument Accent for Honda Goldwing

Niehaus Cycle Sales, Inc.

$31.92

$33.51

Kuryakyn 3241 Motorcycle Accessory: Plug & Play Rear Accessory Harness for 2001-10 Honda Gold Wing GL1800 Motorcycles , black

SVS Power Sports

$18.99

2001 2002 2003 2004 2005 Honda GoldWing GL1800/A Service Shop Repair Manual OEM

DD_Liquidators

$150.00

1984 Honda Gold Wing GL1200 Factory Service Manual Dealer GoldWing Shop Repair Workshop

GLAVIS ENTERPRISES

$49.00

WILD HEART Waterproof Motorcycle Duffel Bag PVC500D With Rope Straps and Inner Pocket 40L 66L 100L for Kayaking, Camping, Boating,Motorcycle

ZHONGSHAN WILD FRUIT OUTDOOR

$100.00

$169.99

1988 Honda Gold Wing GOLDWING GL1500 Service Shop Repair Manual OEM FACTORY 88

GLAVIS ENTERPRISES

slabghost

Well-known member

Sounds right to me. If I am actually reading right.

well moving along i got the relay mostly wired in today and dyna coils installed dosnt sound like much but there was a lot of work being this all up to par after all these yrs connection and all ...finaly got tired of it and worked on the 80 wing some camera down right now :cheeky: :rant: :mrgreen:

well the 80 has its problems too :head bang: now i think today im working mostly on the dragonwing ...this was purely a mised step i made but when check for valve clearence....i didnt put cam seals in or torque the heads yet so today its time to redo belts ...i have new ones and torque the heads as this puppy is ready lower end wise to go ahead for testing ...this will be somewhat a pain but ive done this many times and there pleasure knowing it getting button up to go ...pics coming :mrgreen:

well i did some work today on 1200 but i was also watching the grandson antway belt change time and also put in some cam seals and final cleaning up of valve trane ...and i havent torque heads down yet might be the last thing i do here some pics

1100 head ..76 371 cam..86 1200 motor

after belt pulley and cam removal

after sone clean up and you can see the mark on the left cam journal

it seemed okay to me ill do some cleaning on it ...so i didnt get far but im going :builder: :whip: :mrgreen:

1100 head ..76 371 cam..86 1200 motor

after belt pulley and cam removal

after sone clean up and you can see the mark on the left cam journal

it seemed okay to me ill do some cleaning on it ...so i didnt get far but im going :builder: :whip: :mrgreen:

out side to do some 77 dragonwing work ....beem raining here the couple days ...i sould have lot of time to work on the bike today ...ive pretty much have the ignition relay hook up and coils installed after heads are done it will be time to put in dyna ignition to finish relay and move on to themostat water way on top of motor carbs and drive shaft install sheesh getting there slowly

okay i did torque the heads today ... but since then ive been going over the rockers and cams by hand as to make them better to put together with parts they never been with ...it taking quite a bit of time here the cams seems great but the rockers are definitely sub par to me...this is a custom motor job so its not really regular install with parts that have been together ....there was a lot of goo used in the cam seal area to be cleaned up ...heads get hot fried goo can get hard to get off ...anyway im done for the day

im out to the doghouse to go after the 1200 some more i got fustraited yesterday with the rockers and had to stop ...new day today :builder: :mrgreen:

joedrum said:well after a posting by supperskypilot on the saunders forum ...imight be in deep crap on the use of 1000 heads....he says the water pluming is different and wont work on the 1200 block.....if this is true then i guess 1000 heads wont work on 1100s either....my only option would be if cams and ignition system will fit on 1100 head or drilled and taped to fit it dark and ill have to wait till morning on this.....

The 1000 heads fit onto the 1100 with no mods and allow for the ignition to be moved to the ideal accessible place. If push comes to shove you could always fit 1975-6 cams into the 1100 heads and have the ignition there also which is what I have done to mine. Follow the following link and go to post number 6 where i explain in more detail.

viewtopic.php?f=6&t=3983

well steve had a lot to learn about parts mixing and was a discounter before facts producer .. today the rocker are getting the full treatment of bringing up to par and beyond stock to even better...got pics coming

- Joined

- Dec 3, 2009

- Messages

- 22,443

- Reaction score

- 262

- Location

- Van Nuys Ca.

- My Bike Models

- 1983 Interstate

2018 KLR 650

2018 BMW S1000 RR

- My Bike Logs forum link

- https://classicgoldwings.com/forums/dan-filipi.122/

So water plumbing is ok, Joe?joedrum":3p1ifv71 said:well steve had a lot to learn about parts mixing and was a discounter before facts producer .. today the rocker are getting the full treatment of bringing up to par and beyond stock to even better...got pics coming

yes

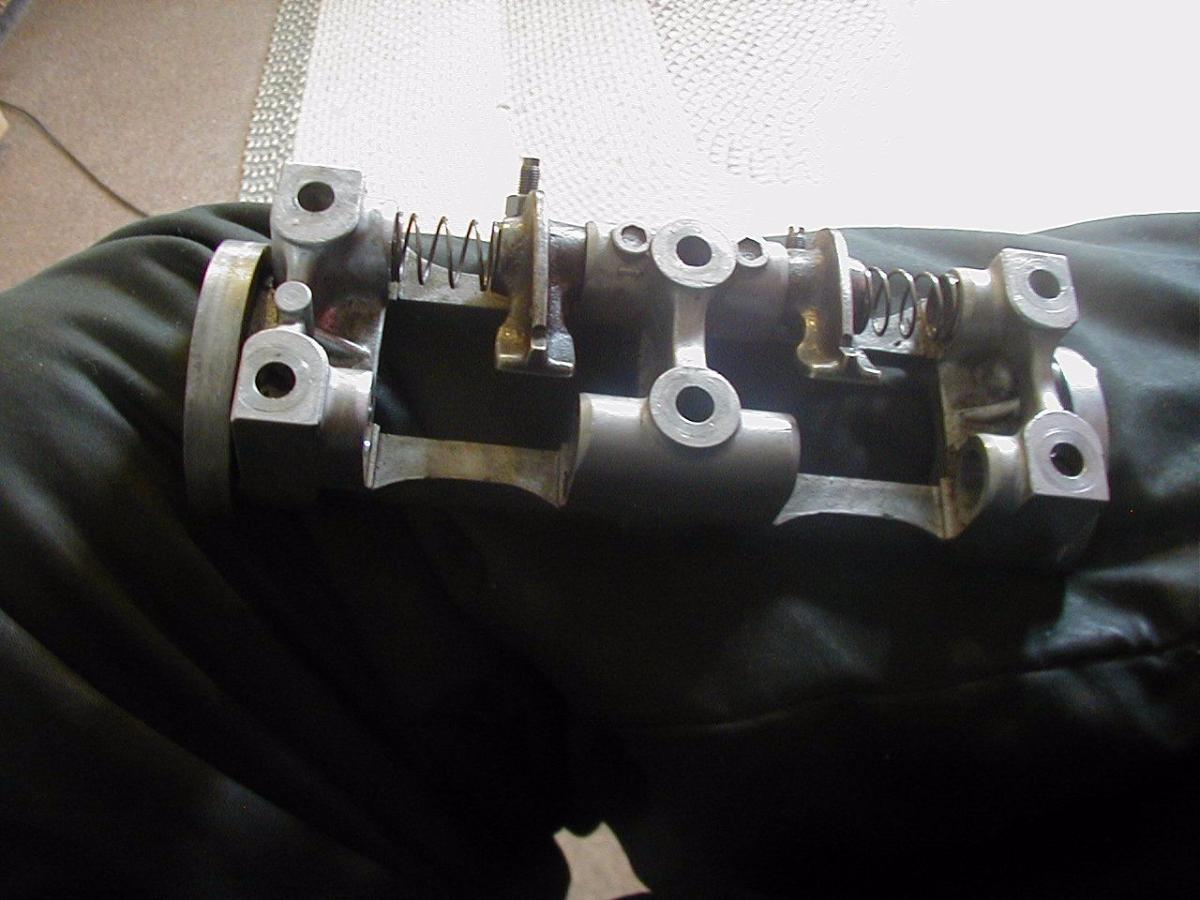

okay today i went through the cam carrier.....traded shafts from one side of cam carrier to the other and have the oil holes point don towards the heads ...and you get all the bolts to go in the holes your good ....what this dose is tighten the rockers to the shaft as now there on new shaft where the springs were before....plus while the rockers were out i trued the surface where they ride the cam ...they really had to to be brought up to par with the cams ...couple pics

this pic shows the shafts out...rockers and springs still on one side ...shaft go out towards the back of motor end....

cant realy see the oil holes ...but this the buttom side of the shafts and you can see where the wear area is with the rocker ...after shafts rotated and hole poiting down rockers are on new shaft area ..this is a simple upgrade to do :builder: :mrgreen:

this pic shows the shafts out...rockers and springs still on one side ...shaft go out towards the back of motor end....

cant realy see the oil holes ...but this the buttom side of the shafts and you can see where the wear area is with the rocker ...after shafts rotated and hole poiting down rockers are on new shaft area ..this is a simple upgrade to do :builder: :mrgreen:

very clever joe. That's using the ol noggin. :good:  opcorn:

opcorn:

BUT where dose the tricycle fit????? :smilie_happy: :smilie_happy: :smilie_happy: