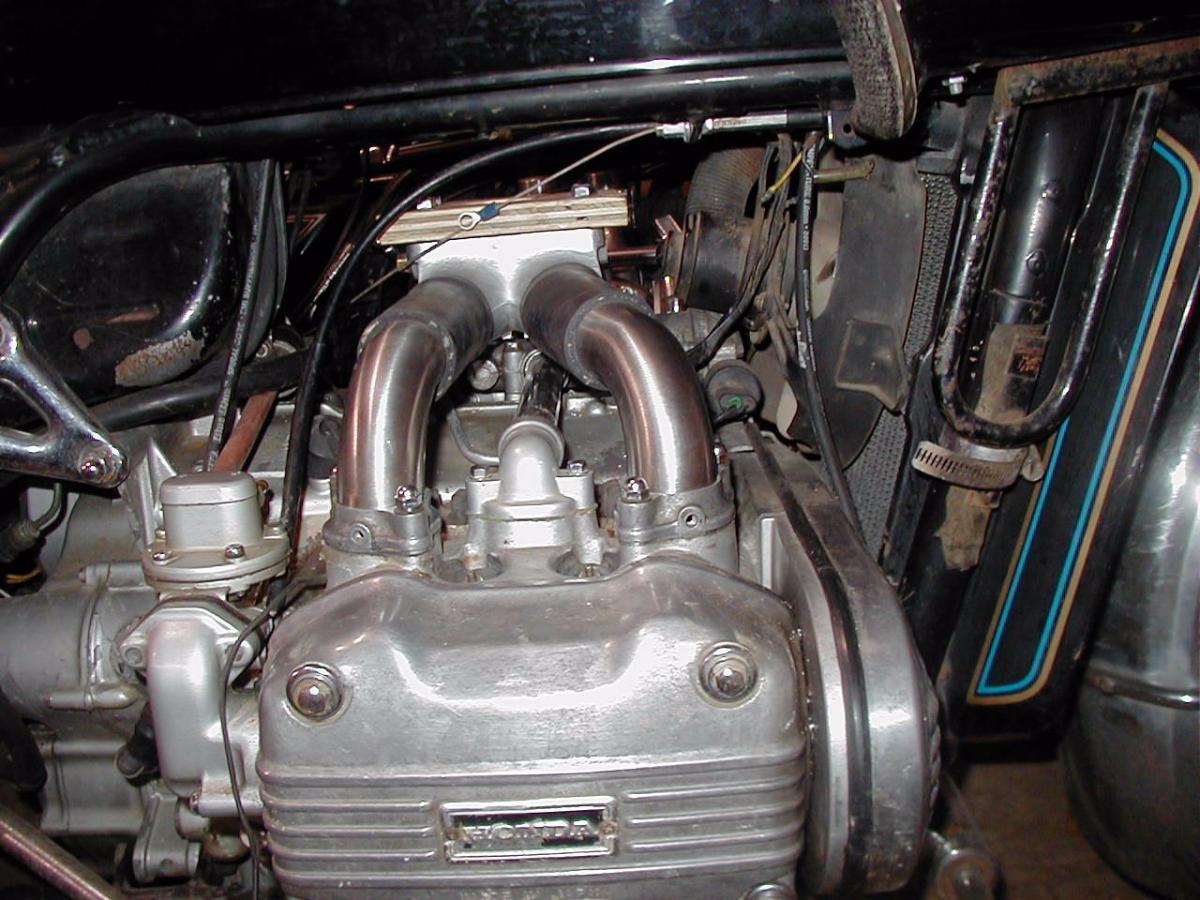

this is a early pic but you can see ... that with a 1 1/2 O ring the set up will seal both ways .. :builder: :thanks:

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

hooch getting a new fuel source

- Thread starter joedrum

- Start date

Help Support Classic Goldwings:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Dec 3, 2009

- Messages

- 9,291

- Reaction score

- 337

- Location

- Duncanville, Texas

- My Bike Models

- 1981 GL1100 Innerstate("The Turd")SOLD!!, 1996 GL1500 Innerstate

That's how he's gunna take all of his air flow/temp/velocity measurements..... :mrgreen:[url=https://www.classicgoldwings.com/forum/viewtopic.php?p=111592#p111592:zuvjnbwr said:ekvh » Mon Mar 03, 2014 3:09 pm[/url]":zuvjnbwr]

Why are you running it through your laptop?

That thing looks perfect, and about as close to looking factory made as you could get. :good:

Joe...you're a true Craftsman....I bow to you, sir!

thanks joel ... but I feel anyone can do this but it dose take patience and great amount of hand skill ... I am not sure others could do this as it is tough to hang in there ....but at least it is evidence that this can be done ... joel right now I feel like I am building the great wall china and I am just haftway don ...2 down 2 to go LOL.. oh my genius title didn't get passed 7th grade then the school began :builder: :thanks:

sheesh pic of progress ...still have some fitting to do ... but looking good so far :builder: :thanks:

It looks so simple but I know how much work has gone into it. :builder:[url=https://www.classicgoldwings.com/forum/viewtopic.php?p=111773#p111773:15lm54ex said:joedrum » Wed Mar 05, 2014 2:35 pm[/url]":15lm54ex]

sheesh pic of progress ...still have some fitting to do ... but looking good so far :builder: :thanks:

~O~

pics

just a couple shots of what it will look like

just a couple shots of what it will look like

$41.81

$54.95

Clymer Honda GL1200, 1984-1987: Maintenance, Troubleshooting, Repair (Clymer Motorcycle)

Haynes Repair Manuals

$9.95

$14.95

BELL Vortex Hinge Plate Kit Street Motorcycle Helmet Accessories - Black/One Size

Movatik

$5.33

$6.49

Pink Balaclava Ski Mask Head Mask Full Face Mask Windproof Sun UV Protection Hood for Women Men

Ligart

$76.00

Honda GL 1800 Gold Wing 2001-2010 Repair Manual (Haynes Service & Repair Manual)

Clickgoodwill

$32.09

$59.95

Honda GL1800 Gold Wing 1800 (01-10) Haynes Repair Manual (Paperback)

Haynes Repair Manuals

$150.00

1984 Honda Gold Wing GL1200 Factory Service Manual Dealer GoldWing Shop Repair Workshop

GLAVIS ENTERPRISES

$46.95

Harley-Davidson Trailblazer #1 Logo Duffel Bag w/Adjustable Strap - Rust Vintage Large

Wisconsin Harley-Davidson

$55.09

$58.00

WILD HEART Waterproof Motorcycle Duffel Bag PVC500D Double-bottom With Rope Straps and Inner Pocket 40L 66L 100L for Kayaking, Camping, Boating,Motorcycle

ZHONGSHAN WILD FRUIT OUTDOOR

$35.37

$45.95

Show Chrome Accessories 52-696 Honda Goldwing GL1800 01-10 Radio Panel

Amazon.com

$129.00

Sena 30K / 20S / EVO Helmet Clamp Kit for Honda Goldwing CB Helmet Accessories

ProRidersClub

$50.07

M506-2 1993-2000 Honda GL1500 Goldwing Clymer Motorcycle Repair Manual

Classic Automotive Repair Shop & Restoration Manuals

$100.00

$169.99

1988 Honda Gold Wing GOLDWING GL1500 Service Shop Repair Manual OEM FACTORY 88

GLAVIS ENTERPRISES

$48.99

$55.00

HONDA GL1000 & GL1100 GOLDWING MOTORCYCLE REPAIR SHOP & SERVICE MANUAL For 1975, 1976, 1977, 1978, 1979, 1980, 1981, 1982, 1983, 1984 & 1985 - NEW, 304 Pages

Classic Automotive Repair Shop & Restoration Manuals

Simple and elegant at the same time, like Mother Honda engineered it herself.

~O~

~O~

- Joined

- Dec 3, 2009

- Messages

- 9,291

- Reaction score

- 337

- Location

- Duncanville, Texas

- My Bike Models

- 1981 GL1100 Innerstate("The Turd")SOLD!!, 1996 GL1500 Innerstate

[url=https://www.classicgoldwings.com/forum/viewtopic.php?p=111799#p111799:82fkbk29 said:Omega Man » Wed Mar 05, 2014 8:39 pm[/url]":82fkbk29]

Simple and elegant at the same time, like Mother Honda engineered it herself.

~O~

+1!!!! Awesome job, Joe!!! You better get a patent on that design, before someone steals it.... :clapping:

If it runs as good as it looks, it will be one amazing machine!

its here for all joel no patent ... this is so difficult and reqires so much touch .. that no machine could do it at all...and I must say it was a good time for me as I have been mostly snow and iced in ... and this kept me inside and made the most of it ...the dang intake runners are very not the same ...I am astonish how mismatched they to the head ports ... rough crummy and quite off .... so it was also very enlighten ...sheesh the mismatch of these intakes has to cause some carb problems ... again to me custom work is leaps and bounds better than factory work ... and it seems most think opposite ...but I am no believer in most for anything ... I don't think I am pushing this deal as the thing for others to try ... someone like me snowed and iced in unable to work or retired ... pass that I think this is way to much for most and the busy deals of life of no time for you .... hmmmm they call this freedom hmmmmm ....LOL thanks for the praise ... as steve 83 said if this works ... im trying big day today ... :builder: :thanks:

- Joined

- Dec 3, 2009

- Messages

- 22,463

- Reaction score

- 275

- Location

- Van Nuys Ca.

- My Bike Models

- 1983 Interstate

2018 KLR 650

2018 BMW S1000 RR

- My Bike Logs forum link

- https://classicgoldwings.com/forums/dan-filipi.122/

Ok.......enough praise, it's making me sick.

Get this bolted down so we can see if it even works and can be sealed.

Get this bolted down so we can see if it even works and can be sealed.

there you go ... shut up and get er done ...ok seems like the boss said quit misspelling words and grab a file ... :smilie_happy: :builder: :mrgreen:

pics

hardly a level surface but enough to be certain that everything is not in a bind and seal even

this pic shows the lower file out that had to be in the clamps to fit flat and not effected by 90 degree turns in runners

hardly a level surface but enough to be certain that everything is not in a bind and seal even

this pic shows the lower file out that had to be in the clamps to fit flat and not effected by 90 degree turns in runners

- Joined

- Dec 3, 2009

- Messages

- 9,291

- Reaction score

- 337

- Location

- Duncanville, Texas

- My Bike Models

- 1981 GL1100 Innerstate("The Turd")SOLD!!, 1996 GL1500 Innerstate

:good:  opcorn:

opcorn:

Joe,

How are you going the stick the runners to the flanges?

How are you going the stick the runners to the flanges?

- Joined

- Dec 3, 2009

- Messages

- 9,291

- Reaction score

- 337

- Location

- Duncanville, Texas

- My Bike Models

- 1981 GL1100 Innerstate("The Turd")SOLD!!, 1996 GL1500 Innerstate

[url=https://www.classicgoldwings.com/forum/viewtopic.php?p=111973#p111973:2lu883n8 said:canuckxxxx » Fri Mar 07, 2014 11:35 am[/url]":2lu883n8]

Joe,

How are you going the stick the runners to the flanges?

:hihihi:

But seriously....I wonder that meself. Stainless is hard to weld to begin with, and fusing it with aluminumnum? :headscratch: Imma guessing some kind of epoxy?

- Joined

- Dec 3, 2009

- Messages

- 22,463

- Reaction score

- 275

- Location

- Van Nuys Ca.

- My Bike Models

- 1983 Interstate

2018 KLR 650

2018 BMW S1000 RR

- My Bike Logs forum link

- https://classicgoldwings.com/forums/dan-filipi.122/

Joe and I have been texting he may tap in set screws.

[url=https://www.classicgoldwings.com/forum/viewtopic.php?p=111973#p111973:g95l02tg said:canuckxxxx » Fri Mar 07, 2014 12:35 pm[/url]":g95l02tg]

Joe,

How are you going the stick the runners to the flanges?

from previous pictures you can see that the runners actually replace the inner ridge of the of the o ring groove almost exactly...it looks to me that 1 1/2 o rings fatter than stock o rings will seal clamps down to head and clamps to runner ... as for hold downs to prevent pop off in blow back of some kind .....I am going to strap down the runners some how to the motor to prevent pop off from happening

I really don't want to make it rigid as floating like it dose now makes for easy sealing without much torque .......is what I am thinking .... :mrgreen:

- Joined

- Dec 3, 2009

- Messages

- 9,291

- Reaction score

- 337

- Location

- Duncanville, Texas

- My Bike Models

- 1981 GL1100 Innerstate("The Turd")SOLD!!, 1996 GL1500 Innerstate

[url=https://www.classicgoldwings.com/forum/viewtopic.php?p=111976#p111976:396ilnre said:dan filipi » Fri Mar 07, 2014 12:30 pm[/url]":396ilnre]

Joe and I have been texting he may tap in set screws.

That was my guess, too. A couple of screws in each flange into the runners would hold them on, without being too solid. A small bead of sealer around the runners before sliding the flanges on, along with the o-rings would guarantee no leeky.

who444444

Well-known member

How about using the threaded hole already in the collar replace existing screw with set screw and run in tight against tube to hold it.

dave

dave