some pics

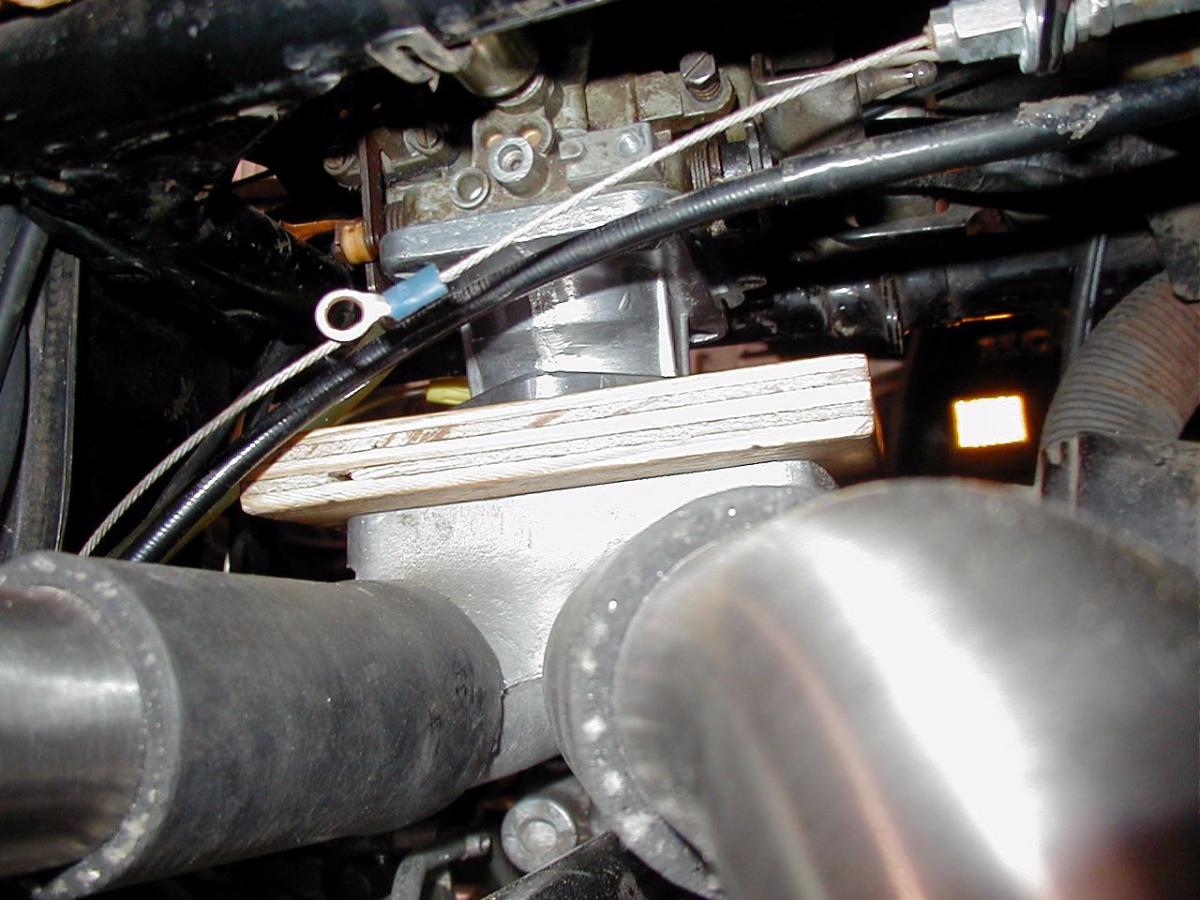

carbs looks like its getting turned 90dgrees ...plenty of room on my plate to stout things up ....mix and idle screw acess is much better ... throttle hook up couldn't stay the same anyway ... so I am going to try this .. :builder: :mrgreen:

carbs looks like its getting turned 90dgrees ...plenty of room on my plate to stout things up ....mix and idle screw acess is much better ... throttle hook up couldn't stay the same anyway ... so I am going to try this .. :builder: :mrgreen: