You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

shock treatment

- Thread starter joedrum

- Start date

Help Support Classic Goldwings:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

manual shows rotor nut going over starter clutch saft ...bolt and all on it ...the stator bolt retains nothing at all ...

- Joined

- Jan 27, 2013

- Messages

- 9,855

- Reaction score

- 34

- Location

- Brisbane Australia

- My Bike Models

- 1981 GL1100 “Rats Nest”

1998 GL1500c Val

1987 CBR1000f “The Pig”

1991 CBR1000f Red

Stator bolt is holding the rotor on ( for my money it should be called rotor bolt but it was probably translated from Japanese :smilie_happy: )

slabghost

Well-known member

Go back and look at the parts blow up. On the 1200 it seems the only purpose for that bolt is to turn the motor for maintenance. Big nut holds the rotor on.

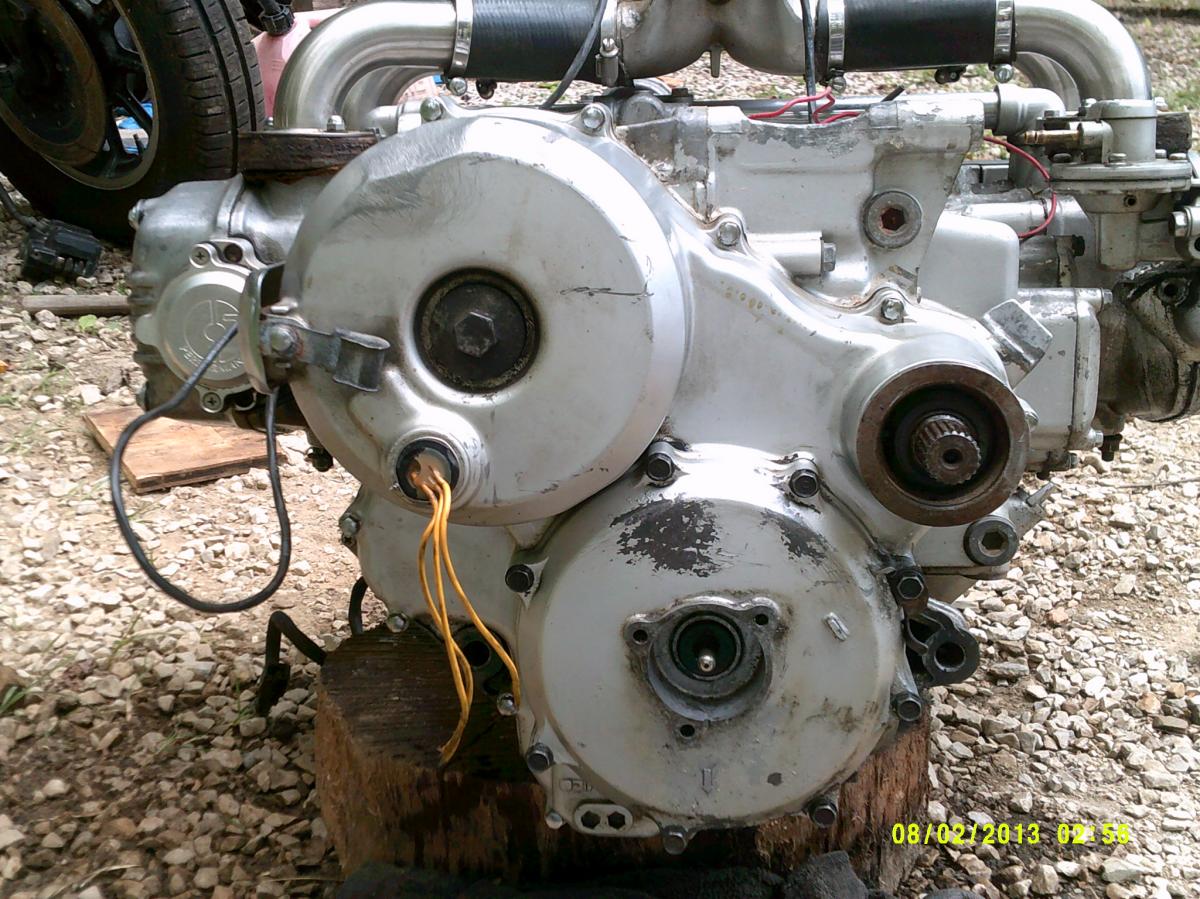

overall im really pleased how clean the motor is ....i have change the oil alot ....seems the bad stator was a blessing in deguise ....the starter clutch shaft bolt for turning the motor ..was a desaster waiting to happen ....there are many things about the 1200 motor that just sets it apart and best the earlier short blocks of the 1000 and 1100 motors...they are actually more capable of high rpm and certainly way more quiet .....in a over all look at things from the shovelking grab bar induction to the inside of motor clean clean clean....for 10,000 miles of summer service this year ...this only adds up to ...things were set up or dial in nice ...the c5 is certainly putting fire in the hole and the custom advance curves are spot on with no window for error ....my highly modded economy car dft epa carb into a big mucle producing power house performance carb seems to be leaving nothing behind in motor and everything going out the exhaust as in power ......considering heads,cams,piston cutouts and total manchanical valves set up....its hard to be anything but satisfied here .....

though this is a stator thread ..everything is always looked at by me ... im not very good at appearence restoration or better put cant afford it ....but inside the heart of the bike ..it shinning nice ...hope to get it all back together today ...need to fine my phillips head for the hand impact wrench... :builder: :thanks:

though this is a stator thread ..everything is always looked at by me ... im not very good at appearence restoration or better put cant afford it ....but inside the heart of the bike ..it shinning nice ...hope to get it all back together today ...need to fine my phillips head for the hand impact wrench... :builder: :thanks:

pics

pic of bike ..i slid away from motor ...put removable frame piece back on so had a side stand ....

pic of bad stator ...

all back together now with new used stator ..from a 1000 ...if you look close you can splug was buggard up ... so i used stainless steel tie wire ...to secure it ....also switch out the output shaft from 1100 to 1200 shaft ...as this is the final ill be using for hooch ... :yahoo: no more clip.......its ready for install ..

ok for the big mod ... as you can see the 1000 timing covers dont really fit 1200 motor ...there short and inner bolt dosnt line up ....so in view of this ... hooch is prime canidate for a crank pulley ...i want help here with ones that have done this ....i have a few wants here ... ive look things over quite well on hooch ...motor and radiator are close ..to lessen that i want to put like a 3" pully i guess the smallest i can get away with ....and i want to have tight up against crank pulley ...ill cut the timing cover back to clear that ...as the belt will not go to one side or the other but strait up ... as alt will be mounted like in coil area of frame .. will be fixed id say and im going to put a spring tensioner on it .... please give thoughts ... :builder: :thanks:

pic of bike ..i slid away from motor ...put removable frame piece back on so had a side stand ....

pic of bad stator ...

all back together now with new used stator ..from a 1000 ...if you look close you can splug was buggard up ... so i used stainless steel tie wire ...to secure it ....also switch out the output shaft from 1100 to 1200 shaft ...as this is the final ill be using for hooch ... :yahoo: no more clip.......its ready for install ..

ok for the big mod ... as you can see the 1000 timing covers dont really fit 1200 motor ...there short and inner bolt dosnt line up ....so in view of this ... hooch is prime canidate for a crank pulley ...i want help here with ones that have done this ....i have a few wants here ... ive look things over quite well on hooch ...motor and radiator are close ..to lessen that i want to put like a 3" pully i guess the smallest i can get away with ....and i want to have tight up against crank pulley ...ill cut the timing cover back to clear that ...as the belt will not go to one side or the other but strait up ... as alt will be mounted like in coil area of frame .. will be fixed id say and im going to put a spring tensioner on it .... please give thoughts ... :builder: :thanks:

$76.00

Honda GL 1800 Gold Wing 2001-2010 Repair Manual (Haynes Service & Repair Manual)

Clickgoodwill

$9.95

$14.95

BELL Vortex Hinge Plate Kit Street Motorcycle Helmet Accessories - Black/One Size

Movatik

$35.37

$45.95

Show Chrome Accessories 52-696 Honda Goldwing GL1800 01-10 Radio Panel

Amazon.com

$48.99

$55.00

HONDA GL1000 & GL1100 GOLDWING MOTORCYCLE REPAIR SHOP & SERVICE MANUAL For 1975, 1976, 1977, 1978, 1979, 1980, 1981, 1982, 1983, 1984 & 1985 - NEW, 304 Pages

Classic Automotive Repair Shop & Restoration Manuals

$55.09

$58.00

WILD HEART Waterproof Motorcycle Duffel Bag PVC500D Double-bottom With Rope Straps and Inner Pocket 40L 66L 100L for Kayaking, Camping, Boating,Motorcycle

ZHONGSHAN WILD FRUIT OUTDOOR

$14.99

$17.99

MELASA Fleece Lined Winter Cycling Beanie with Holes for Glasses - For Men, Women

HNXCHUANG

$50.07

M506-2 1993-2000 Honda GL1500 Goldwing Clymer Motorcycle Repair Manual

Classic Automotive Repair Shop & Restoration Manuals

$46.95

Harley-Davidson Trailblazer #1 Logo Duffel Bag w/Adjustable Strap - Rust Vintage Large

Wisconsin Harley-Davidson

$32.09

$59.95

Honda GL1800 Gold Wing 1800 (01-10) Haynes Repair Manual (Paperback)

Haynes Repair Manuals

$100.00

$169.99

1988 Honda Gold Wing GOLDWING GL1500 Service Shop Repair Manual OEM FACTORY 88

GLAVIS ENTERPRISES

$150.00

1984 Honda Gold Wing GL1200 Factory Service Manual Dealer GoldWing Shop Repair Workshop

GLAVIS ENTERPRISES

$129.00

Sena 30K / 20S / EVO Helmet Clamp Kit for Honda Goldwing CB Helmet Accessories

ProRidersClub

$41.81

$54.95

Clymer Honda GL1200, 1984-1987: Maintenance, Troubleshooting, Repair (Clymer Motorcycle)

Haynes Repair Manuals

slabghost

Well-known member

Sounds like a nice mod but I'm having a bit of trouble picturing it. Maybe an 1800 alternator can be fitted easiest.

Yep, sorry I thought I was on the 1200 car tire post. So finding an entire 1500 rear end would be the ticket with a 1200 swing arm. Thanks, Joe.

id say so eric if you want to use the 1500 16" wheel on the 1200 swing arm ...

ok on this thread i just placed a order for the fan in ? here ... 22$ delivered to me ...only bad part is date expected to arrive is 14th of this month....so things are coming together ...i will get bike ready to ride today ..wheel back on ..wiring all chalk and seal up....i will be putting original crank bolt and no pulley back on ..as i want the pulley with me when getting new bolt and a proper sleeve for the pulley..i had just a plastic sleeve in it while modding things to fit .... :builder: :thanks:

ok on this thread i just placed a order for the fan in ? here ... 22$ delivered to me ...only bad part is date expected to arrive is 14th of this month....so things are coming together ...i will get bike ready to ride today ..wheel back on ..wiring all chalk and seal up....i will be putting original crank bolt and no pulley back on ..as i want the pulley with me when getting new bolt and a proper sleeve for the pulley..i had just a plastic sleeve in it while modding things to fit .... :builder: :thanks:

- Joined

- Jan 27, 2013

- Messages

- 9,855

- Reaction score

- 34

- Location

- Brisbane Australia

- My Bike Models

- 1981 GL1100 “Rats Nest”

1998 GL1500c Val

1987 CBR1000f “The Pig”

1991 CBR1000f Red

Don't know how hot it is for you Joe but the Rats Nest's fan is manually switched only and it doesn't get used very often unless it is hot and stuck in traffic or grinding up the DD.

i just mounted the radiator back the fan not there ...im not to worried either ...about running with no fan where i live ...man the room it opens up... :shock:

pics

heres a crappy pic of the jd restictor plate im going to try

nice better pic ..what you cant see is the spring is still in use and holds the plate in ..you can take plate out change it or another plate used with different hole ..the reallity is this didnt take long ..im starting out small first and see how is dose ......im sure theres a sweet spot here to match cooling system ..and i want to find it ... :builder: :thanks:

heres a crappy pic of the jd restictor plate im going to try

nice better pic ..what you cant see is the spring is still in use and holds the plate in ..you can take plate out change it or another plate used with different hole ..the reallity is this didnt take long ..im starting out small first and see how is dose ......im sure theres a sweet spot here to match cooling system ..and i want to find it ... :builder: :thanks:

slabghost

Well-known member

Looks waaay to small from my house! Watch the temp gauge.

- Joined

- Dec 3, 2009

- Messages

- 22,463

- Reaction score

- 275

- Location

- Van Nuys Ca.

- My Bike Models

- 1983 Interstate

2018 KLR 650

2018 BMW S1000 RR

- My Bike Logs forum link

- https://classicgoldwings.com/forums/dan-filipi.122/

Sweet spot for what Joe?

slabghost

Well-known member

Warm up time and proper cooling at speed I suppose.

- Joined

- Dec 3, 2009

- Messages

- 22,463

- Reaction score

- 275

- Location

- Van Nuys Ca.

- My Bike Models

- 1983 Interstate

2018 KLR 650

2018 BMW S1000 RR

- My Bike Logs forum link

- https://classicgoldwings.com/forums/dan-filipi.122/

This is getting off topic also. A new topic would be better Joe.

for constant coolant flow ...to raise or lower tempeture to ideal flow rate to move heat heat better ..it not something im strong about ...but wioll learn something here ..so i posted it so others know all that going on in this work session on hooch ....certainly more than a stator change happen ..was there plan ..not really but ideas yes ...

pics :BigGrin:

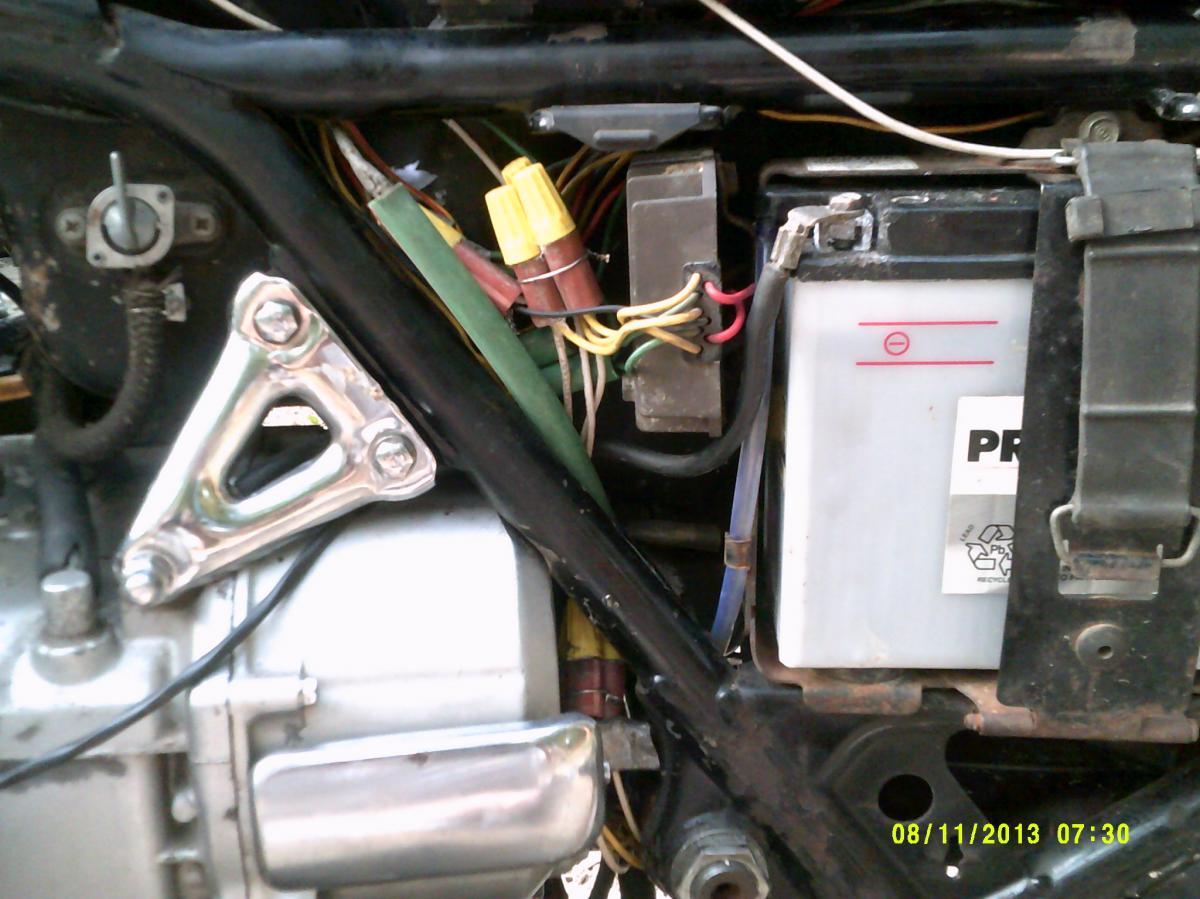

ok wiring going on ..wires being sealed with chalk and and incased with wirenut and wire collers for the wires out of cutting torch sprap hose...

stator wires done the sam way ...wires will be grouped together but way more apart than connectors that are done away with ..

mess fixing to do ...there plenty of room for improvment and its time .. :smilie_happy: :builder: :thanks:

ok wiring going on ..wires being sealed with chalk and and incased with wirenut and wire collers for the wires out of cutting torch sprap hose...

stator wires done the sam way ...wires will be grouped together but way more apart than connectors that are done away with ..

mess fixing to do ...there plenty of room for improvment and its time .. :smilie_happy: :builder: :thanks:

pics :BigGrin:

wiring in battery box came out nice ...has 1980 reg-rec put in to replace 1000 set up ..of reg and rec that are seperate units ....long green hose piece just covers those wires ..i just left them for now ....the reds are the stator wires hook to 1980 reg-rec ...the greens tuck in low there are grounds for 1980 reg-rec ...the red wires going behind battery are the charging wires ...like the green grounds there doubled but essintially do the same thing ...two wires doing the same thing makes one big wire .....the lower stator wires are behind the behind the stator and just under frame tube... these stator wires are turn up to tread water....all groups of wires are tied together with stainless steel tie wire...

above the long green sleeve of wires not used you can see where honda connected the wires together in the gray wrap ...this use to be under the black wrap ... sheesh it can cause all kinds of stator resistance in one third of the stator and a inbalance of flow constantly ..between the stator and reg ..the 2 most heat producing things and this three way connector goes through electric hell ..and it hidden when stock this is a 1000 thing only ..this is all gone now ..should have done it before ..the last time i had trouble with charging .....got it now anyway .. :builder: :thanks:

wiring in battery box came out nice ...has 1980 reg-rec put in to replace 1000 set up ..of reg and rec that are seperate units ....long green hose piece just covers those wires ..i just left them for now ....the reds are the stator wires hook to 1980 reg-rec ...the greens tuck in low there are grounds for 1980 reg-rec ...the red wires going behind battery are the charging wires ...like the green grounds there doubled but essintially do the same thing ...two wires doing the same thing makes one big wire .....the lower stator wires are behind the behind the stator and just under frame tube... these stator wires are turn up to tread water....all groups of wires are tied together with stainless steel tie wire...

above the long green sleeve of wires not used you can see where honda connected the wires together in the gray wrap ...this use to be under the black wrap ... sheesh it can cause all kinds of stator resistance in one third of the stator and a inbalance of flow constantly ..between the stator and reg ..the 2 most heat producing things and this three way connector goes through electric hell ..and it hidden when stock this is a 1000 thing only ..this is all gone now ..should have done it before ..the last time i had trouble with charging .....got it now anyway .. :builder: :thanks:

slabghost

Well-known member

Nice job! Looks very neat and organized.